Buying Guide for the Best Binding Machines

Choosing the right binding machine can make your document organization and presentation much easier and more professional. Before you buy, think about how often you'll use the machine, the volume of documents you need to bind, and the type of finish you want for your documents. Understanding the key features will help you select a machine that matches your needs, whether it's for occasional home use, regular office tasks, or high-volume professional projects.Binding CapacityBinding capacity refers to the maximum number of sheets a machine can bind together in one go. This is important because it determines how thick your finished documents can be. Machines with lower binding capacities (up to 100 sheets) are suitable for light, occasional use, such as small reports or booklets. Medium capacity machines (100-300 sheets) are good for regular office use, while high-capacity machines (over 300 sheets) are designed for heavy-duty or professional environments. To pick the right one, consider the typical size of the documents you need to bind and choose a machine that can handle your largest expected project.

Punching CapacityPunching capacity is the number of sheets the machine can punch holes through at once. This matters because it affects how quickly you can prepare your documents for binding. Low punching capacity (up to 10 sheets) is fine for occasional or home use, but can be slow for larger jobs. Medium capacity (10-20 sheets) suits most office needs, while high capacity (over 20 sheets) is best for frequent, high-volume tasks. If you often bind thick documents or need to save time, look for a higher punching capacity.

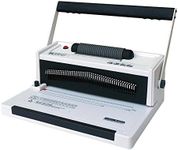

Binding StyleBinding style refers to the type of binding the machine uses, such as comb, wire, coil, or thermal. Each style has its own look and function. Comb binding is versatile and easy to edit, wire binding offers a more professional finish, coil binding allows pages to turn 360 degrees, and thermal binding gives a book-like appearance. Your choice should depend on the appearance you want, how often you need to add or remove pages, and how the documents will be used.

Manual vs. Electric OperationBinding machines can be operated manually or electrically. Manual machines require you to punch and bind by hand, which is fine for small volumes or occasional use. Electric machines automate some or all of the process, making them faster and easier for frequent or high-volume tasks. If you expect to bind many documents regularly, an electric machine can save time and effort, while a manual machine is more suitable for light, infrequent use.

Document Size CompatibilityThis spec tells you what sizes of paper the machine can handle, such as A4, letter, or legal size. It's important because using the wrong size can lead to misaligned holes or unfinished edges. Most machines are designed for standard sizes, but if you need to bind custom or larger documents, make sure the machine supports those sizes. Always match the machine's compatibility with the types of documents you plan to bind.

Adjustable Margin DepthAdjustable margin depth lets you control how far the holes are punched from the edge of the paper. This is important for both the appearance and durability of your bound documents. A deeper margin is better for thicker documents to prevent pages from tearing out, while a shallower margin can be used for thinner documents. If you work with a variety of document thicknesses, look for a machine with adjustable margin depth for more flexibility.

Build Quality and SizeThe build quality and size of the machine affect its durability and how much space it will take up. Heavier, sturdier machines are better for frequent use and will last longer, while lighter, more compact machines are easier to move and store, making them suitable for occasional or home use. Consider where you will use and store the machine, and how often you need to move it, to choose the right build and size for your needs.